Understanding the Difference: Bamboo Viscose vs Bamboo Lyocell

When it comes to choosing eco-friendly fabrics, it can all seem a little confusing. Both viscose and Lyocell are fibres derived from renewable plant materials, but the way they are produced makes a significant difference in their environmental impact and performance characteristics.

Production Process

Viscose, also known as rayon, is produced through a chemical process that dissolves plant pulp (such as bamboo) using chemicals like sodium hydroxide and carbon disulphide in a method known as the xanthation process. This process is not closed-loop, meaning it can release harmful byproducts into the environment unless properly managed

On the other hand, Lyocell is produced using an organic solvent in a closed-loop process. This method recycles around 99% of all of solvents used, significantly reducing harmful emissions and waste. The closed-loop process not only makes Lyocell more environmentally friendly but also enhances some other characteristics.

Texture and Durability

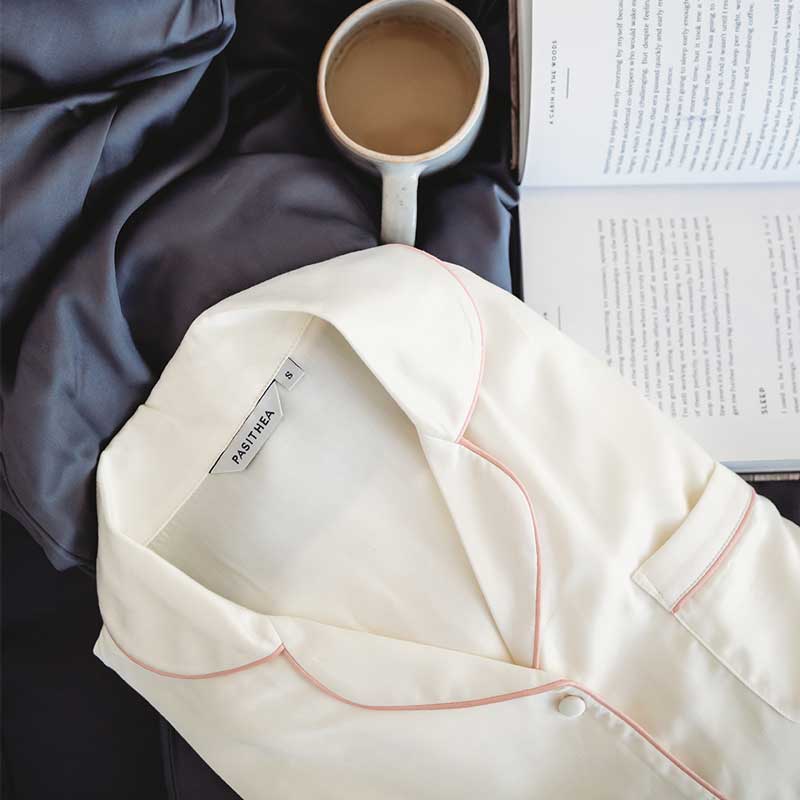

Lyocell fibres are generally stronger and softer than viscose fibres. They have a smooth surface that drapes beautifully and resists creasing, making them ideal for high-quality bedding and sleepwear. Viscose, while also soft and often also less expensive, tends to be weaker and more prone to tearing when wet, making it less durable over time.

Moisture Management

Both fibres are known for their breathability and moisture-absorbing qualities, but Lyocell outperforms viscose in moisture management. Lyocell fibres are more efficient at wicking moisture away from the body, contributing to better hygiene and comfort, especially important in sleepwear and bedding.

Eco-Friendliness

Lyocell's eco-friendly production process gives it a significant advantage over viscose. With a lesser environmental impact and more sustainable manufacturing practices, Lyocell aligns better with modern environmental standards, making it a superior choice for consumers looking to make responsible choices.